Introducing Tisfoon Quattro

Introducing the all new Tisfoon Quattro cut-off saw optimizer. Designed specifically for cutting 6 inch and under material. It is non-marring, so ideal for cutting finished products and moulding. High cut accuracy and high cut quality. Cut as many lengths as you like at the same time. The computer will handle the optimization and can even complete all the sizes at the same time. Save on yield and material.

The Tisfoon Quattro can be used with our automatic defect/grading scanner, or traditional line marking.

For Cross-Cutting

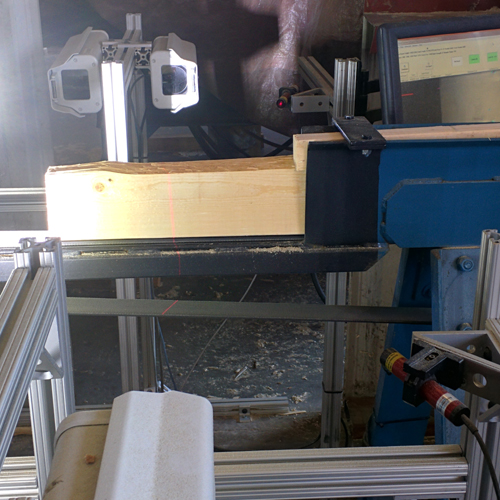

The lumber defect scanner uses cameras and lasers to automatically grade and defect lumber. It replaces

traditional line marking with a fluorescent crayon. Operators no longer need to know the grading rules.

Your product will have a more consistent look and will not depend on the operator.

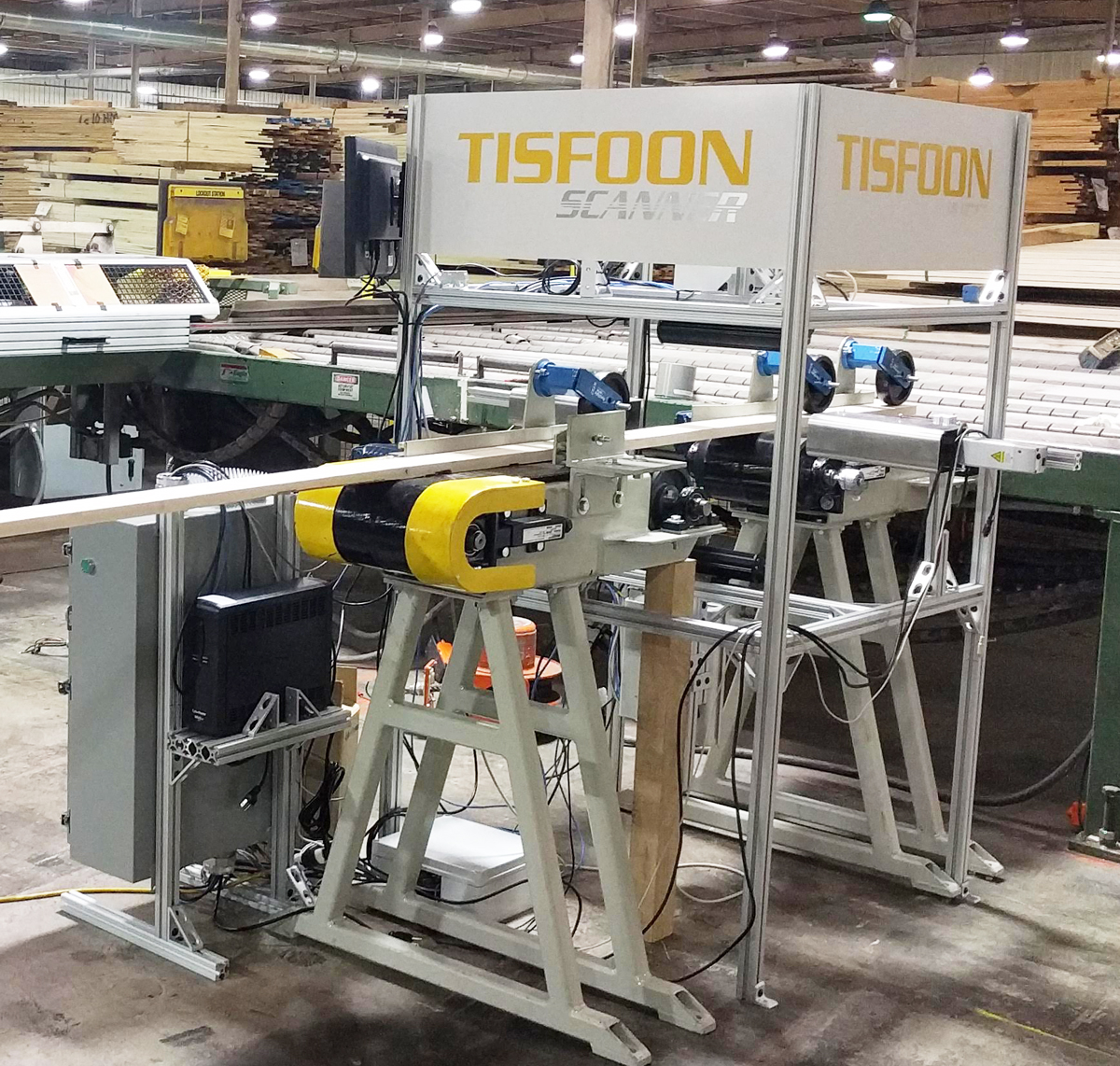

For Ripping

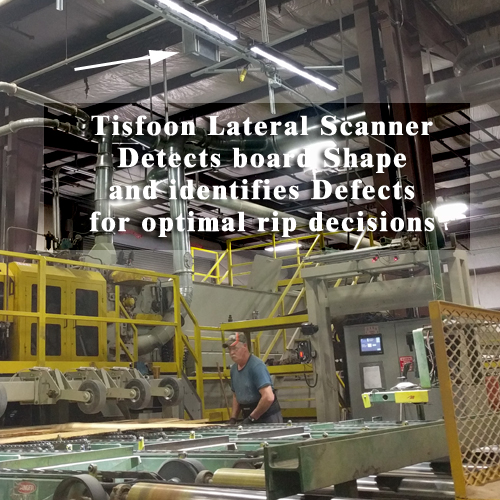

Traditional rip saw feeders shine a laser line on the board showing the rip positions and then the operator has to make adjustments before the board is dealt into the rip saw. With the Tisfoon Lateral Scanner, cameras look at the board and pick up defects and find the optimal way to feed the board into the rip saw.

|

|

For Cross-Cutting or Ripping

If you already have equipment that is mechanicaly fine, but is lacking intelligence, or has obsolete hardware and software, then retrofitting is much less expensive than buying new. We have retrofit packages for a host of woodworking equipment.

|

|

BMI Brute Retrofit BMI CompuRip Retrofit Dimter Retrofit Ultimizers Retrofit

Services:

Lumber Industry - Rough Mill At Tisfoon, we've been revolutionizing wood processing since 1994 with innovative, affordable machinery and services tailored for efficiency and precision. Independent of conglomerates, we collaborate seamlessly with any vendors, ensuring flexibility for your operations. Our core offering is automatic defect detection machinery, using advanced cameras to identify knots, wane, cracks, worm holes, and more in wood boards. This technology integrates with our optimizing cut-off saws for superior yield.

The lighter-duty Quattro cut-off saw optimizer is ideal for smaller operations, providing reliable cross-cutting based on camera grading data.

For heavier-duty needs, our brand-new Model 5 cross-cut optimizer stands out. This robust machine handles boards up to 12 inches wide and 2 inches thick, delivering precise cuts informed by real-time defect and shape analysis. Paired with our very affordable defect scanner, it enables direct feeding for streamlined production. Multiple lines can run independently, scaling your output without interference.

We also provide shape-detecting cameras that optimize board placement into rip saws, enhancing overall workflow. Complementing this is our arbor generation software for rip saws, which intelligently plans blade positions to maximize material use and minimize waste.

Retrofit services are a specialty: upgrade your existing optimizing cut-off saws or Raimann movable blade rip saws with our absolute encoder servo motors. This eliminates homing requirements, reducing constant calibration and downtime for cost-effective modernization.

What sets us apart is unmatched service; phone, text, and emails are always free. We offer complimentary remote service, allowing us to access your machines for quick diagnostics and support, keeping your operations running smoothly.

Discover how Tisfoon delivers value through innovation, affordability, and reliability at tisfoon.com.

Did we mention we also automated ALL the hydraulics at the KA show at the MGM Grand in Las Vegas? Click the link below for more information:

Lighting & Sound America: A look at the scenic automation, projection, and show control systems in KA

©1994-2023 TUS, Inc. 3434 Edwards Mill Rd. Suite 112-326 Raleigh, NC 27612 USA