Industrial Machinery Automation

PC Control of Machinery

We specialize in designing software to automate industrial machinery. We have automated machinery in the woodworking, packaging, ceramic powder, powdered metal, fabric cutting, and entertainment fields. We have designed these machines from the ground up including the realtime control engine, motion control, optimization algorithms, and human machine interfaces (HMI). The machines run robustly 24/7 in factories.

Industrial machinery has to be reliable and robust and we have numerous customers and machines in the field that can attest to that.

As you read this, our software is producing wood for furniture and hardwood flooring, powedered metal parts for the auto industry, cutting fiber for

upholstry, and moving a 150 ton hydraulic stage in Las Vegas for the entertainment industry.

| Cirque du Soleil - KA |

We wrote the software to move the stage and safety nets for Cirque Du Soleil's KA show at the MGM Grand in Las Vegas.

The stage moves 70 feet vertically and tilts 100 degrees.

There are 18 winches controlling 2 safety nets. We incorporated our VCR, locoMotion, and Code Generator technologies for a robust

product.

Click here for more information.

The stage moves 70 feet vertically and tilts 100 degrees.

There are 18 winches controlling 2 safety nets. We incorporated our VCR, locoMotion, and Code Generator technologies for a robust

product.

Click here for more information.

|

| Eagle Talon Cutoff Saw | The Talon cross cuts lumber in an optimal fashion. It uses our motion controller package which

consists of the Delta Tau controller and the Advanced Digital logic PC104 computer. The HMI runs on

Windows 2000. The optimization algorithms produce superior cut decisions as compared to the competition

and they are fast. The saw is capable of blowing waste as small as 1/4 of an inch on a conveyor running

at 130 inches per second.

consists of the Delta Tau controller and the Advanced Digital logic PC104 computer. The HMI runs on

Windows 2000. The optimization algorithms produce superior cut decisions as compared to the competition

and they are fast. The saw is capable of blowing waste as small as 1/4 of an inch on a conveyor running

at 130 inches per second.View Application Note |

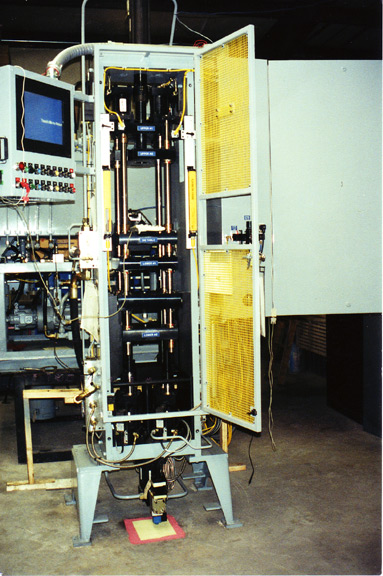

| 250-750 Ton Hydraulic Press | This hydraulic press has 1 upper punch and 1 lower punch. It uses the Delta Tau Turbo PMAC

controller in a UMAC configuration. Position is repeatable to 3 ten thousands of an inch. Force

control is overlayed on position with an accuracy of 0.1 tons. Each of the upper and the lower

have two 3-way valves and one 4-way valve controller. This allows for both high speed travel and

accurate positioning.

controller in a UMAC configuration. Position is repeatable to 3 ten thousands of an inch. Force

control is overlayed on position with an accuracy of 0.1 tons. Each of the upper and the lower

have two 3-way valves and one 4-way valve controller. This allows for both high speed travel and

accurate positioning. View Application Note |

| 20 Ton Hydraulic Press | This hydraulic press has 2 upper punches and 3 lower punches. It uses the Delta Tau Turbo PMAC

controller in a UMAC configuration. Position is repeatable to 3 ten thousands of an inch. Force

control is overlayed on position with an accuracy of 0.1 tons.

controller in a UMAC configuration. Position is repeatable to 3 ten thousands of an inch. Force

control is overlayed on position with an accuracy of 0.1 tons.

|

| FiberMaster | The FiberMaster is a two dimensional fiber/fabric Cutter CNC machine. It uses 2 axis for

X axis motion coordinated with a single axis for Y axis motion. The machine

cuts the fabric on the fly.

It has 16 digital inputs

and 8 digital outputs. Motion control is via a 6 axis PCX/DSP card from Motion Engineering, Inc.

The software was written in Borland Delphi, and uses LocoMotion.

cuts the fabric on the fly.

It has 16 digital inputs

and 8 digital outputs. Motion control is via a 6 axis PCX/DSP card from Motion Engineering, Inc.

The software was written in Borland Delphi, and uses LocoMotion.

|

| Compu-Rip II | The Compu-Rip is a Rip Saw optimizer used in the rough mill. It has a sophisticated

Arbor Generator that produces near optimal blade arrangement.

It has 16 digital inputs

and 8 digital outputs. Motion control is via an 8 axis PCX/DSP card from Motion Engineering, Inc.

The software was written in Borland Delphi, and uses LocoMotion.

Arbor Generator that produces near optimal blade arrangement.

It has 16 digital inputs

and 8 digital outputs. Motion control is via an 8 axis PCX/DSP card from Motion Engineering, Inc.

The software was written in Borland Delphi, and uses LocoMotion.

|

| Wonder Saw | The Wonder Saw is used in the rough mill to optimize cross-cutting of

|

| Compu-Rip | The Compu-Rip is used in the rough mill to optimize ripping of wide boards. We used the 8 axis Motion Engineering PCX-DSP card and the Contec IRT16 interrupt card. It is driven by 8 Yaskawa Servo drives and has 32 inputs, 16 outputs, and 16 interrupt inputs. The software is written in Borland C++ and runs in DOS real mode. The device is networked to other machines via a central Command Center using RS-485. |

| See Me Bag Machine | The Bag Machine produces bags to cover furniture. This bag is both see through and padded and so may be used both on the showroom floor and during shipping. The machine is driven by 12 Endramat servo motors and uses two 6 axis Motion Engineering PCX-DSP motion control cards. It has 16 inputs and 16 outputs. The software was written with Borland Delphi. |

©1994-2023 TUS, Inc. 3434 Edwards Mill Rd. Suite 112-326 Raleigh, NC 27612 USA