Custom Optimization Algorithms

One Dimensional Integer Programming (Stock Cutting), Two Dimensional Nesting

1D Stock Cutting is of 2^N complexity. In the lumber industry, there is the additional complexity of grade merging.

Our algorithm is capable of solving this combinatorial problem efficiently, quickly, and at optimal yields.

Cut to Required Amount: In the manufacturing production line, required amounts and zero inventory are more important than high yield. Therefore, our algorithm is also capable of cutting to the specified required amount while also keeping the yield high. This is accomplished by making slight adjustments to the value of each size during the production process.

Batch Mode Order Processing: Completing orders on a first in first out basis is vital to the custom kitchen cabinet manufacturer and custom furniture manufacturer. These custom shops have a large number of sizes to cut with low quantity required amounts. Our algorithm handles this job by processing the first order to the required amount. As sizes drop out from the current order, sizes are borrowed from upcoming orders to keep the yield constant throughout the production process. Taking sizes from upcoming orders is done with some restraint, otherwise, there is going to be a handling issue down the line.

Machine Syncronization: Typically multiple machines work on a single job and the optimization needs to be coordinated over these machines. We accomplish this syncronization through broadcast network communication thus making each machine aware of the others' progress.

Arbor Generation: our Virtual Rough Mill product produces high yielding arbors which also match production requirements. It even suggests solid sizes for panel stock. This feature is specially important for kitchen cabinet manufacturers.

2D Irregular Shaped Polygon Nesting: Our nesting program is efficient and fast. Any irregular shaped polygon may be nested within another irregular shaped polygon.

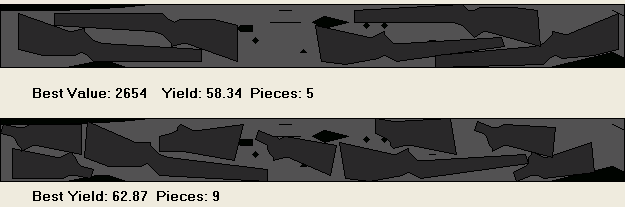

In this image, we have nested three parts within a board bypassing defects and wane. The top image demonstrates value optimization and the lower image demonstrates yield optimization.

In both images, parts were not allowed to rotate beyond 12 degrees (due to wood grain requirements).

Yield, Value, and Production Requirement optimization modes are available. Since the nesting problem

is NP-complete, please contact us for a custom fit algorithm to solve your nesting application quickly and efficiently.

Yield, Value, and Production Requirement optimization modes are available. Since the nesting problem

is NP-complete, please contact us for a custom fit algorithm to solve your nesting application quickly and efficiently.

©1994-2023 TUS, Inc. 3434 Edwards Mill Rd. Suite 112-326 Raleigh, NC 27612 USA